Cycle Stop Valves Can Save as Much Energy as a Variable Speed Pump

Head produced by a pump drops off by the square of the speed. Pumps that must lift a certain distance or produce a specific pressure (or TDH) have a minimum speed that will accomplish this task. The speed of a correctly sized pump can only be reduced a small amount if a static head or constant pressure is required. Horse power reductions by the cube of the speed can be insignificant compared to a full speed pump simply pushed to the left of it's curve. Before you can use the Affinity Law the following steps must be taken to determine the minimum speed possible from your pump. The affinity law can then be used to determine the minimum horsepower possible from your pump when using a VFD.

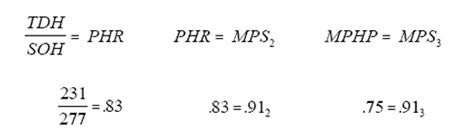

Total Dynamic Head or (TDH) sets the minimum speed allowed. Divide the (TDH) by the pumps Shut Off Head (SOH). The answer will be a percentage of head loss possible or Possible Head Reduction (PHR). Minimum Possible Speed or (MPS) squared equals the Possible Head Reduction (PHR). (MPS) cubed equals the minimum percentage of Horse Power or Minimum Possible Horse Power (MPHP).

For example:

| Take a 10 HP 100 GPM pump that deadheads at 120 PSI | SOH = 120 |

| The constant pressure required is 100 PSI | TDH = 100 |

| Possible Head Reduction is 83% of deadhead | PHR = .83 |

| Minimum Possible Speed is 91% of full RPM | MPS = .91 |

| Minimum Possible Horse Power is 75% of full load | MPHP = 7.5 Horse Power |

To maintain a Constant Pressure this pump can only be slowed by 9%. This only reduces the Horse Power from 10 to 7.5.

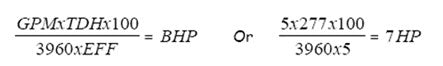

Choking back a full speed 100 GPM pump to 5 GPM the efficiency drops to 5%. Using these figures along with a TDH of 277' the standard BHP rule follows.

When a constant pressure or (TDH) is required, choking this pump back with a Cycle Stop Valve saves more energy than the Variable Speed Pump. Using the affinity law the variable speed only reduced the 10 HP to 7.5 HP. The Cycle Stop Valve simply de-rated the full speed 10 HP to a 7.0 HP load.