Pump Stations: CSV vs VFD

Conserving water is even more important than conserving energy. Many systems lose 30% to 50% of their water to leaks in the system. Anytime water is wasted, not only is that precious resource lost forever, but the energy used for pumping is also wasted. If the water is treated, even further losses accumulate. Eliminating leaks in the system not only conserves water, but may also be the best way to conserve energy.

Water hammer is the number one cause of leaks. Transient pressure waves cause water hammer. These waves travel from 3,000 to 8,000 feet per second inside the pipe line. When these waves hit a dead end, closed valve, or an elbow, they cause water hammer spikes of up to 10 times the regular operating pressure. As these waves bounce off dead ends and elbows, the high spike in pressure is followed by a negative pressure wave. A pipeline operating at 100 PSI can regularly experience shock waves of 1,000 PSI or more. However, the resulting negative pressure wave can cause as much damage as the pressure spike. An audible thump may be the only thing noticed, until the pipe splits, an elbow is blown off, or small cracks appear. Water then begins gushing up from the ground, or steadily dripping into it. Large line breaks and small continuous drips, waste tremendous amounts of our precious fresh water, and the energy used to produce it, everyday.

Transient pressure waves are created anytime a tap in the system is opened or closed, a pump is started or stopped, or when pump controls react slowly. Water in motion wants to stay in motion, and water at rest wants to stay at rest. Anytime water in a pipeline is made to start moving or stop from moving, pressure waves are formed, and water hammer is emanate. In the past, attempts to eliminate water hammer have included the use of slow operating valves, soft starters, surge suppressers, and countless other devices. This is much like trying to catch a bullet with your teeth. The same way it is impossible to catch a bullet traveling at 3,000 feet per second with your teeth, it is also impossible to catch a 3,000 feet per second shock wave with something that reacts slowly.

Pump controls with extremely fast reactions, can eliminate transient pressure waves before they turn into water hammer. Just how and what device can operate this fast? Well, before you can understand how it works, you must rid your mind of some "myths" you have been led to believe.

Even though it is a myth, some people still believe that VFD's can save energy. This is understandable because many VFD proponents understand electronics but, do not understand the mechanical characteristics of centrifugal pumps. In their minds it is completely logical that reducing the RPM of a pump would reduce energy consumption. They do not understand that even though the amps are reduced as the RPM is reduced, a VFD always causes more energy to be used per gallon produced. Many people even become angry at those who say VFD's do not save energy. This anger usually comes from their lack of understanding. The fact is that in most applications, there is very little if any difference in energy consumption between a Valve and VFD controls. A VFD is just trying to trick a pump into doing something it already does naturally.

Parasitic and efficiency losses from a VFD, adds to the increase in energy used per gallon. VFD's also cause harmonics, voltage spikes to the motor, and EDM or (bearing currents) that destroy bearings. Resonance frequency vibration is also a problem, as some speeds are critical. Problems also occur with cooling the motor, because fan speed is reduced along with the motor speed. Environmental concerns as well as technical assistance can be expensive. Having to regularly replace the VFD and repair motors, continually adds to the expense. Anyone of these problems should be sufficient cause to look for an alternative control. Other control options should always be considered, because there is nothing magical about VFD's. A little research is all that is needed to understand why VFD's do not save energy, and why other options maybe preferable.

Even though it is also a myth, many people still believe that controlling a pump with a valve is like "driving a car with one foot on the gas and the other on the brake". Many people first think that restricting with a valve will make a pump work harder. This is not true. Restricting with a valve actually makes a pumps work easier, and reduces the amp draw. It is one of the few things in life that is truly counter intuitive, which makes it hard to understand. When seeing this with their own eyes, even engineers for some of the major pump manufacturers have said, "they didn't realize the amps would drop so low by simply restricting the pump with a valve".

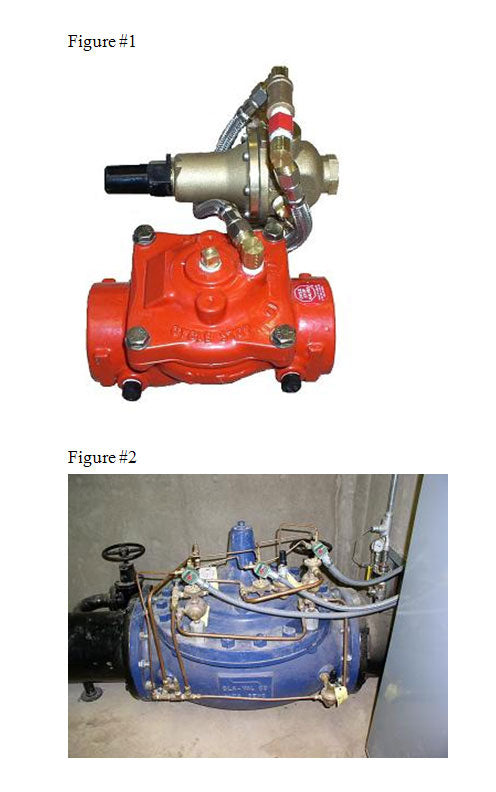

Even those who do understand that Valves can be as efficient as VFD's, may still argue that valves require a lot of maintenance, are slow reacting, difficult to adjust, and experience wear. These people are simply not aware of recent advances in Valve design. Figure #1 shows a Cycle Stop Valve in red, next to an old style conventional pump control valve in blue in Figure #2. You can see that the Cycle Stop Valve or CSV, has considerably fewer controls than the old style control valve. The insides of the CSV are just as simple by comparison.

The patented non-closing design of the CSV makes all the difference. The CSV is designed to never close, so valve and seat wear is inconsequential. The non-closing feature also allows the CSV to function extremely fast. A fast reaction from an older style fully closing valve will cause water hammer on opening and closing. The CSV uses a much larger pilot valve. The larger pilot commands the CSV to operate extremely fast, and also allows debris to pass through. This eliminates screens, needle valves, and small orifices that were known to be problems with older style pump control valves. There is only one adjustment on the CSV. One bolt on the pilot easily sets the desired pressure, and never needs adjusting again. All these things combined produce a valve that operates fast enough to eliminate water hammer, doesn't need regular maintenance, does not fail because of minor wear, is extremely easy to adjust, and saves just as much energy as a VFD.

Transient wave canceling technology is the highlight of the CSV, and cannot be duplicated by other valves or VFD's. The CSV reacts so fast that a positive pressure wave is instantly met with a decrease in flow, and a negative pressure wave is instantly met with an increase in flow, which cancels out transient pressure waves before they cause water hammer. This is much like noise canceling technology of some headphones.

Many CSV controlled pump stations, installed as far back as 1994, have required little to no maintenance on pumps or pipelines. Low cost up front, over 16 years of service with very little if any maintenance, while conserving water and the related energy, offers a tremendous return on investment.

After installing CSV's, line breaks at many golf courses, municipalities, dairies, greenhouses, etc., in some cases dropped from 300 leaks per year, to only 3 leaks per year. Eliminating leaks not only conserves tremendous amounts of water but, also conserves the related energy.

None of the problems associated with VFD exist when using a Valve for control. With a Valve, the motor is always spinning at full RPM but, the amps are reduced similarly to varying the speed. When the motor is spinning at full speed, the cooling fan always provides adequate cooling. Spinning at full speed also means there are no problems with resonance frequency vibrations. Running on pure sinusoidal power, instead of the unstable waveform produced by a VFD, means there are no problems with harmonics, voltage spikes, or bearing currents.

A manufacturer of VFD pump stations said in a recent article; "it is not advisable to get caught up in an overly elaborate system just because the technology's available. With the advancements in the electronic industry, it's tempting to add complexity to the electronics of a pump station. It is recommended that people keep things as simple as possible. When you add complexity, it doesn't always make the application better suited for the job. With more complex electronics, the maintenance and repairs can become more complex and difficult, and often there is not much value added. It is important that irrigation professionals understand what the electronics can and can't do. No one wants to get dazzled by bright lights, only to find out that their product is not easy to maintain."

Nothing is as simple as a CSV, and that is part of what makes it so advanced. The CSV has no wires or electric components. The system pressure directly powers the CSV. This means the CSV can react instantly to any change in pressure, which is much faster than a VFD can change the RPM of a motor.

While other manufacturers keep adding electronics and making systems more complicated, the simplicity of the Cycle Stop Valve sets companies like W.C. Smith Manufacturing apart from the others. Figure #3 shows a recent pump station manufactured by W.C. Smith Manufacturing. Using Cycle Stop Valves to enhance the natural flow and horsepower characteristics of pumps eliminates the need for VFD's and their associated side effects.

Valves have gotten a bad rap from people who honestly myth-understand. However, the expensive and short-lived nature of VFD systems, are more profitable for the manufacturer. Therefore, finding a reputable pump station manufacturer, means finding one who admits that a VFD does not save energy, and Valve control is not like "driving a car with one foot on the gas and the other on the brake".

"Any intelligent fool can make things bigger and more complex. It takes a touch of genius and a lot of courage to move in the opposite direction." Albert Einstein